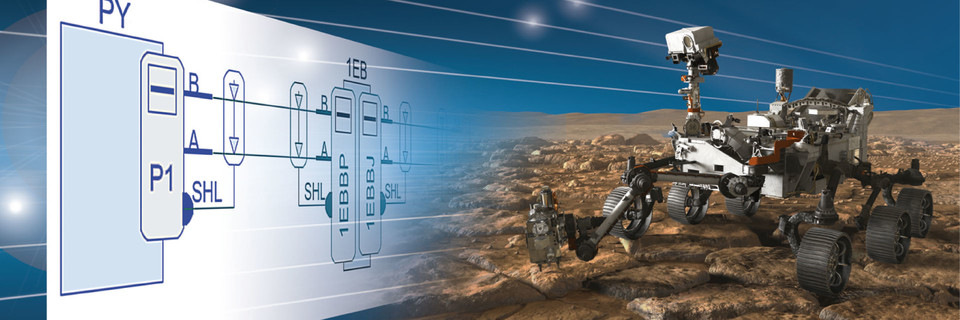

NASA-JPL adopts Concept Engineering’s E-engine and EEvision technologies to develop electronics for missions to Mars and Jupiter

System-visualization software will enable JPL engineers to develop and manufacture space system electronics more quickly, efficiently and reliably across multiple teams

Freiburg, Germany – May 24, 2019 – Concept Engineering, specialists in visualization in debugging technology for electronic circuits and systems, today announced that NASA’s Jet Propulsion Laboratory will use Concept Engineering’s E-engine™ and EEvision™ system visualization software to develop electronics for space missions to Mars and Jupiter moon Europa.

JPL, a federally funded research and development center managed for NASA by Caltech, is implementing different programs in planetary exploration, Earth science, space-based astronomy and technology development. To enable these different missions and programs, JPL develops complex electrical systems and wire harness designs. The process to capture requirements and implement designs for these complex electrical systems is a highly iterative and cyclical.

JPL is currently implementing a model-based, requirements-driven process to improve the development process for future missions and projects. JPL selected E-engine and EEvision to provide system and harness visualization capabilities for this new model-based development process.

“We are proud to support NASA/JPL to get their missions and projects into space more quickly and more reliably,” said Gerhard Angst, CEO and president of Concept Engineering. “With many different team members working on flight projects, JPL was eager to use our cloud-based visualization functionality to provide different team members with instantly available, accurate and up-to-date system schematics.”

NASA-JPL is using the technology to develop electrical systems for several high-profile projects:

- Mission Mars Sample Return: This proposed mission will be to return samples from the surface of Mars to Earth. The mission would use robotic systems and a Mars ascent rocket to collect and send samples of Martian rocks, soils and atmosphere to Earth for detailed chemical and physical analysis.

- The Psyche Mission: Psyche is a journey to a unique metal asteroid orbiting the Sun between Mars and Jupiter. What makes the asteroid Psyche unique is that it appears to be the exposed nickel-iron core of an early planet, one of the building blocks of our solar system.

- Mission to Europa “Europa Clipper:” NASA's Europa Clipper will conduct detailed reconnaissance of Jupiter's moon Europa and investigate whether the icy moon could harbor conditions suitable for life.

E-engine’s and EEvision’s unique capabilities to automatically generate and visualize system diagrams and harness cable diagrams supports JPL’s new model-based development flow and significantly reduces development efforts by replacing manually drawn and maintained schematic diagrams with on-the-fly, auto-generated schematic diagrams and easy access to engineering data via cloud-based access.

E-engine’s and EEvision’s features help:

- Save development, manufacturing and test time,

- Reduce errors in schematic diagrams providing auto-generated correct-by-construct pictures,

- Allow easy access to any system function with on-the-fly visualization or incremental system exploration,

- The development process for complex electronical systems will be more reliable and faster,

- Provide development, manufacturing and test teams easy and instant access to consistent design data.

E-engine and EEvision are available for Windows, Linux platforms and online through web browsers (JavaScript and WebAssembly), providing access from a range of computer and mobile devices, with no installation headaches. E-engine and EEvision ensure that technicians will always be working with the latest schematics and schematic fragments optimized and generated exactly for the task/job they need to perform.

Automotive and Aerospace companies can be sure that no outdated schematic drawings are being used to build and repair their vehicles. Technicians must often deal with static schematic diagrams covering many product variants. The ability to quickly render a schematic of a problem area, based on variant specific vehicle identification numbers (VIN) or diagnostic trouble codes (DTC), represents a leap forward in manufacturing and service efficiency.

About Concept Engineering

Concept Engineering is a privately-held company based in Freiburg, Germany, that provides visualization and debugging technology for electronic circuits and systems, including automatic schematic generation technology for all major design levels. The company’s technology helps electronic design engineers to easily understand, debug, optimize and document electronic designs. Concept Engineering’s software technology is used in many fields in the EDA, Automotive and Aerospace markets, including: RTL development, IP reuse, ASIC and SoC design, FPGA design, analog/ mixed-signal design, logic synthesis, design verification, test automation, post-layout analysis, debugging and visualization at system level, RTL level, netlist level and transistor level.

E-engine and EEvision are trademarks of Concept Engineering GmbH, in the United States and other countries. All other trademarks are property of their respective owners.

Contacts:

Concept Engineering

Gerhard Angst, +49-761-47094-0, info@concept.de, www.concept.de

Cayenne Communication LLC for Concept Engineering

Michelle Clancy, +1-252-940-0981, michelle.clancy@cayennecom.com